Cutting Machine Lineup

2-spindle Slicing MachinesDLS-3225

Equipped with 2 spindles.

Multi-gang blades of different dimensions allow rectangular dicing

Features

- 1. 2-spindle mount!

- 2. Cuts with multi blade of blade thickness of 100 μm

- 3. Scale-up model DLS3240 available in the same series with dramatically improved productivity!

Suitable Materials

■ Maximum workpiece size: 250 mm x 250 mm

- Shape

- Suitable

products - ・Ceramic capacitors

・Optical glass

- Type

Structural Advantages

2 spindles

Enables large rectangular cutting!

Multi-gang blades of different pitch dimensions can be used for cutting CH-1 and CH-2. Makes not only square, but rectangular dicing possible.

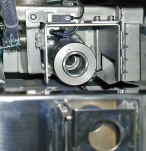

Scale-up model[DLS-3240]

![Scale-up model[DLS-3240]](images/img_dls3225_2.jpg)

Handles workpieces up to 400 x 400!

The 400 x 400 mm chuck table dramatically improves productivity.

Standard Specifications

2-spindle Slicing Machines

DLS-3225

| Chuck table | (mm) | 400 x 400 | |

|---|---|---|---|

| X axis | Effective cutting stroke Minimum indexing setting unit Feed speed range Axis drive system Drive source Axis control system |

(mm) (mm) (mm/sec) |

400 0.001 0 - 150 Rotates precision ball screw with motor shaft to drive AC servo motor Semi-closed loop control by the servo controller |

| Y axis | Effective cutting stroke Minimum indexing setting unit Feed speed range Axis drive system Drive source Axis control system |

(mm) (mm) (mm/sec) |

400 0.001 0 - 50 Rotates precision ball screw with motor shaft to drive AC servo motor Full-closed loop control by linear scale feed back |

| Z axis | Effective stroke Minimum indexing setting unit Feed speed range Axis drive system Drive source Axis control system |

(mm) (mm) (mm/sec) |

40 0.001 0 - 50 Rotates the precision ball screw through the reduction gear from the motor shaft to drive AC servo motor Semi-closed loop control by the servo controller |

| θ axis | Rotation range Minimum resolution Drive source |

(°) | 110 360°/4096000 pulses Direct drive motor |

| Workpiece chuck table | Chuck table design Workpiece sizes (substrate sizes) handled Vacuum source |

(mm) |

Hole type chuck table that uses vacuum to chuck substrate 350 x 350 Ejector-type vacuum generator |

| Spindle | Type Speed range Speed control Motor Blade size |

(rpm) (kw) (kw) (mm) |

Belt drive type ceramic ball bearing spindle 3,000 - 8,000 5.5 Spindle inverter 3.7 Low vibration motor OD φ70 x ID φ40 |

| Alignment microscope | Microscope specifications Microscope magnification LCD monitor Overall magnification on monitor View size on the monitor |

(mm) |

Oblique lighting microscope 2x 15" touch panel Approx. 127x 1.87 x 1.75 |

| Operation | Operation panel Functions other than those on the panel |

Start, Select and Change-over switches for mechanical parts, as well as Status Function Data Input and image display Control power ON/OFF switch, safety release, manual pulsar handle |

|

| Display | 3-color light display | ||

| Electrical components | X, Y and Z axes θ axis Entire unit |

Controlled using a servo controller DD motor PC control |

|

| Transfer section | Cassette system Drive source Reversible motor |

Rotation type belt cassette Number stored in cassette 9 plates on the loader side, and 9 plates on the unloader side |

|

| Accuracy | X axis straightness In the vertical plane Table top accuracy Y axis index accuracy Indexing Z axis repeatability Rotation accuracy of blade axis ・Radial direction runout ・Thrust direction runout |

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) |

In the horizontal plane 0.01/500 0.01/500 0.02 (350 x 350) Repeatability 0.005 0.01/250 0.005 0.002 or less 0.002 or less |

| Utility | Power: Power supply Power: Power consumption Power: Power supply noise Power: Grounding Air source: Air source pressure Air source: Consumption Air source: Dew point Air source: Residual oil content Air source: Connector Coolant water: Supply pressure Coolant water: Flow rate Coolant water: Connector |

(kVA) (MPa・G) (l/min) (PPM Wt/Wt) (MPa・G) (l/min) |

Three-phase AC 200 V within ±10% 50/60 Hz 12kVA 2000 V or less at pulse width 500 ns (square wave) JIS third class grounding resistance 100 Ω or less 0.5 – 0.55 (approx. 5.0 – 5.5 kgf/cm2/G) 300 (A.N.R)) (including 2 vacuum chucks ) -15℃ or less 0.1 Rc (PT) 3/8" female screws/or urethane tube fittings of OD 10 0.15 – 0.3 (approx. 1.5 – 3 kgf/cm2/G) 30 (MAX) Rc (PT) 3/8" female screws (both supply and emission)/or fittings for 15 x 22 blade hose |

| Machine size | Main unit (including conveyance) Electrical box |

(mm) (mm) |

(W) 2650 x (D) 1970 x (H) 1970 (W) 900 x (D) 450 x (H) 1170 |

| Machine weight | Main unit Transfer section Electrical box |

(kg) (kg) (kg) |

2800 240 300 |

*The specification of this machine may be changed for improvement without notice.

*Please contact our sales department for cutting application inquiries on this machine.