Cutting Machine Lineup

Core Drill MachinesDAR810

- Features/Dimensions

- Suitable Materials

- Structural Advantages

- Standard Specifications

- Download Our Brochure

Numerous highly precise round shapes cut in a single process!

Fully automatic machine is able to core faster and with higher efficiency.

Features

- 1. Cuts round shapes from flat plates

- 2. Concentric processing like a doughnut cut is also possible.

- 3. Optimal for many kinds of encoders

Suitable Materials

■ Maximum workpiece size: 200 mm x 200 mm

- Shape

- Suitable

products - ・Servo motor encoders

・Silicon rectifiers

・Optical filters

・PZT substrates

- Type

- *Suitable for highly precise cutting of thick materials.

(Up to 30 mmt)

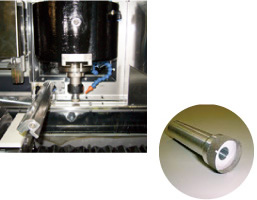

Structural Advantages

Core drill

- ・Cylindrical diamond blade turns at high speed

・Quick processing with less chipping

Glass processing sample

・Applicable to ceramics, Si and various type of materials

Standard Specifications

Core Drill Machines

DAR810

| Chuck table dimension | (mm) | 200 x 200 (Movable range: 200 x 180) | ||

|---|---|---|---|---|

| X axis | Feed speed range Index setting range Drive source |

(mm/sec) (mm) |

0.1 - 200 0.001 - 200 AC servo motor (Linear scale) |

|

| Y axis | Index setting range Index speed Drive source |

(mm/sec) (mm) |

0.001 - 180 MAX 40 AC servo motor (Linear scale) |

|

| Z axis | Effective stroke Cutting height setting range Minimum index step Max move speed Processing speed Drive source |

(mm) (mm) (mm) (mm/sec) (mm/sec) |

75 0.001 - 75 0.001 MAX 20 0.06 - 20 AC servo motor |

|

| θ axis | Rotation range Minimum resolution Drive source |

(°) (°) |

110 360/2,621,440 DD motor (15 Nm) |

|

| Spindle | Type Rotation speed range Rotation control system Motor Core drill (Blade) size Safety interlock |

(min-1) (kw) (mm) |

Direct drive, ball bearing spindle 2,000 - 12,000 Frequency conversion, no-step shifting type via inverter 2.2 2P OD φ3.1 - φ80 x φ20 (shank diameter) 1.Spindle stops at the waterproof cover open. 2.Spindle will not rotate with cover unclosed. |

|

| Operation panel | Touch panel | Showing the operation switch, cutting data, parameter setting, error massages, etc. | ||

| Auto transferring system | Cassette to cassette, 2 cassettes loading | |||

| Accuracy | Table top accuracy X axis index accuracy Y axis index accuracy Z axis index accuracy Spindle rotation run out θ axis index accuracy |

(mm) (mm) (mm) (mm) (mm) (") |

0.02/200 x 200 Accumulative error ±0.01/200 Accumulative error ±0.01/180 Accumulative error ±0.01/75 Spindle radial run out Accumulative error 25"/360° |

Repeatability ±0.005 Repeatability ±0.005 Repeatability ±0.005 0.003 |

| Utility | Power Power consumption Air source pressure Air consumption |

(KVA) (MPa) (l/min) |

3 phase 200 V 50/60 Hz 8 0.55 Driving source: 200 (A.N.R) |

Air shower: 1,440 (A.N.R) |

| Coolant supply unit | Coolant water pressure Coolant consumption (MAX) Power consumption |

(MPa) (l/min) (kVA) |

0.3 30 2 (cooler unit) |

|

| Spindle cooling unit | Cooling unit power consumption | (kVA) | 0.8 | |

| Machine body size/weight | (mm)/(kg) | 1,975 (W) x 1,500 (D) x 1,890 (H) / 1,000 | ||

| Coolant unit dimensions/weight (option) | (mm)/(kg) | 1,140 (W) x 960 (D) x 1,310 (H) / 120 (empty) | ||

*The specification of this machine may be changed for improvement without notice.

*Please contact our sales department for cutting application inquiries on this machine.